1

/

of

5

Astaclift

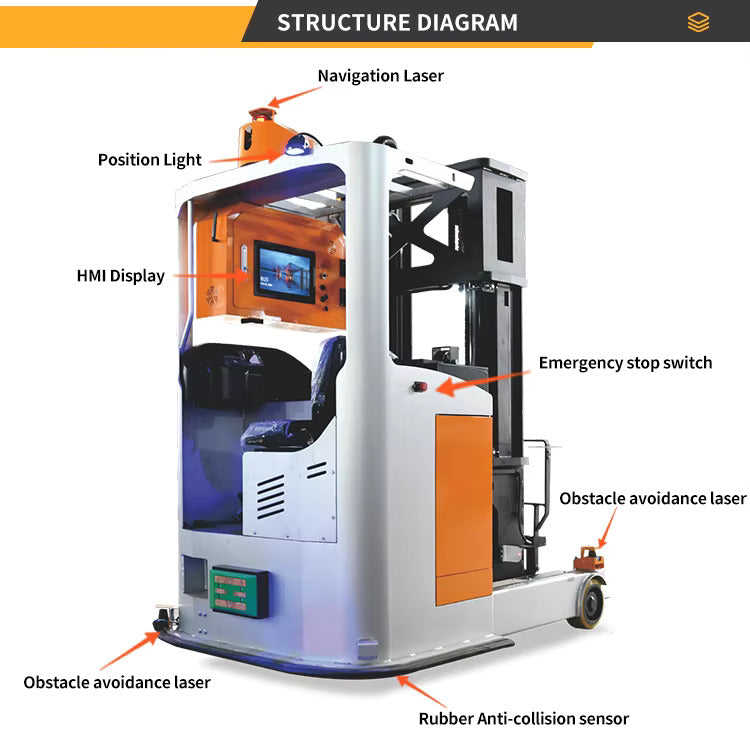

Fully Automated AGV Forklift Automation AS/RS Reach Truck

Fully Automated AGV Forklift Automation AS/RS Reach Truck

Couldn't load pickup availability

Reach Truck High-Level AGV Forklift Solution for industrial

Key Challenges & Solutions

-

1. High-Density Storage Optimization

Challenge: Efficient inbound/outbound management in space-constrained shuttle racking

2. Precision AGV-Shuttle Integration

Challenge:

Sub-5mm placement accuracy required for shuttle-rail alignment;

2.7m narrow AGV pathways;

Solution: Custom laser-guided reach AGVs with enhanced positioning (±3mm);

Value Delivered

6 reach truck AGVs + shuttle system achieve:

✅ 70% labor reduction vs manual handling;

✅ 3x efficiency gain over traditional forklifts;

✅ 100% safety record post-implementation;

Product Advantages:

-

1. Narrow Aisle, High Lift, Precision Handling:

The mast can fully extend and retract, supporting a max load of 2T and a lift height of 12m;

Min. stacking aisle width 2700mm for efficient space utilization;

Autonomous high-precision positioning in natural environments, equipped with high-sensitivity perception modules;

Features pallet detection & placement verification, enabling adaptive material handling with ±10mm repeat placement accuracy;

2. Enhanced Stability:

6.5m high-strength H-type mast steel structure, ensuring superior rigidity and minimal deformation.Optimized for high-level stacking stability;

3. Multi-Scenario Flexibility:

Supports warehousing (in/outbound), floor-to-floor transport, and high-rack storage operations.

Share